Reliable solutions for the

building materials industry.

Our new milestones make your concrete block production even more efficient.

On this page our Masa concrete heads

present the latest milestones.

At Masa, we think only concrete

... and how to shape it for the building materials industry. The machines we develop and manufacture are used for the production of concrete blocks and pavers, sand-lime bricks and aerated concrete blocks. In other words, we are real concrete heads with a passion for reliable machines.

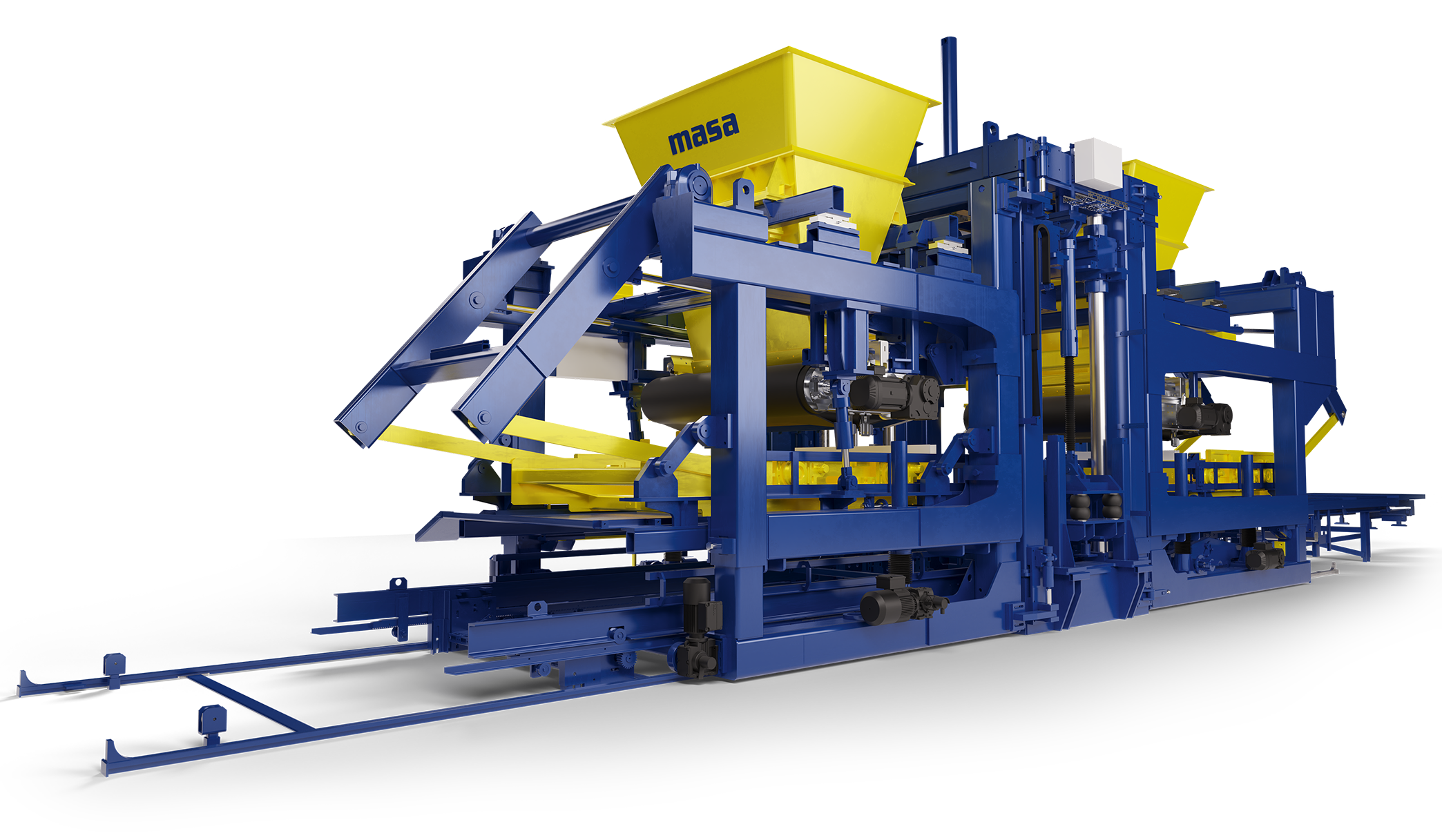

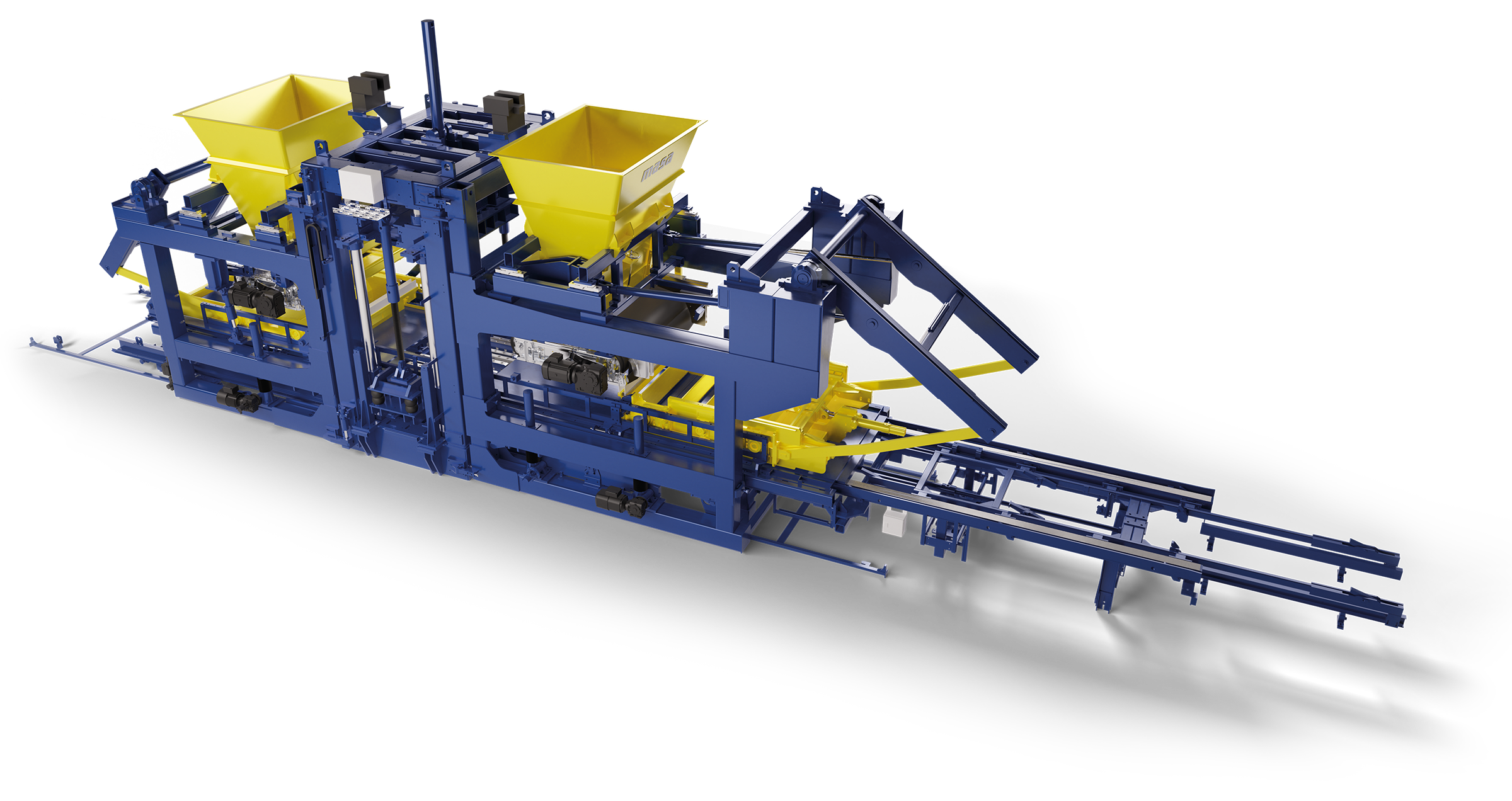

Highly efficient and cycle time optimised.

„My milestone enables you to reliably forecast your production success.“

Marc Reinert, team leader of the design department and thus one of our designing concrete heads, has worked together with his team on the development of our cycle time professional: The Masa XL-R.

You want to know everything about how to produce more products in the same time with the same number of employees? Don't miss the next news on this topic! Click to sign up for our milestone newsletter.

Digitization of concrete block production.

"My Milestone protects you from losing your recipe and process data."

One of our smart concrete heads, Markus Feix, has developed a solution that saves your concrete block production from recipe and plant data loss: Masa Smart Backup.

You see that you need to take care of your data? Don't miss the next news on this topic! Click to sign up for our milestone newsletter.

Many companies still manage technical documentation in a traditional way.

„My milestone makes your technical documentation and spare parts catalog available anytime and anywhere.“

Alexandra Bockhorst, one of our smart concrete heads, has been instrumental in moving the MasaDoc project forward. She has developed a quick access for your team to all information for their maintenance work.

Get in contact with our Service department for further information or register to the milestone-newsletter.

Highly efficient and

cycle time optimised.

Since we have designed this model series particularly for the requirements of the gardening and landscaping sectors as well as large products, we equip the Premium Line machines right from the start with many product and cycle time-oriented features for modern concrete block and paver production. The energy-efficient servo technologies we use should be specifically mentioned in this regard.

That is our XL-R:

- Servo hydraulics with hydraulic accumulators

- Mould bearing synchronisation via servo-controlled hydraulics

- Cycle time optimisation through:

• Intelligent drives

• Servo-controlled, fast feed of the production boards in combination with a synchronised V-belt lowering device

• Overlapping movements

• More energy-efficient drive systems - Set-up time optimisation through magnetic clamping of the filling box rails

- Laser-controlled level measurement in the filling box

- Larger configuration possibilities

- Extensive standard equipment

- Automation applications to support intuitive operation and reliable plant performance

Subscribe to the newsletter

for news and updates.

Subscribe to the Masa milestone newsletter now!

Don't miss any future milestones for your efficient building materials production. Sign up for our newsletter.